In the quest for maximizing agricultural yield and ensuring crop health, innovative technologies are constantly emerging. Among these advancements, the Efficient Agro Shade Net Making Machine stands out as a game-changer. This revolutionary tool is designed to rapidly produce high-quality shade nets with exceptional durability and UV protection. The machine's advanced design incorporates intelligent features that ensure accurate cutting, reinforced stitching, and consistent net production.

- With its user-friendly controls, the machine is suitable for both novice and experienced users.

- Farmers can now quickly manufacture shade nets tailored to their specific needs, protecting against harsh sunlight.

- The budget-friendly nature of this machine makes it a practical investment for agricultural businesses, contributing to their profitability.

Optimal Shade Net Manufacturing Solutions

Shade nets are vital for safeguarding crops and plants from the strong sun. To guarantee high-quality shade nets, manufacturers need to implement effective solutions throughout the production process. This includes implementing advanced equipment for fabric knitting, precise quality control measures, and responsible practices.

By implementing these strategies, manufacturers can produce durable, reliable shade nets that meet the demanding needs of cultivators.

Heavy-Duty Grade Net Making Machine for Agriculture

For ranchers seeking to maximize their production, an heavy-duty|robust net making machine is an essential tool. These machines are built to rapidly produce high-quality nets for a range of applications, such as crop protection, livestock containment, and fish farming. An industrial grade net making machine provides several benefits over manual net production methods, including increased efficiency, improved net durability, and minimized labor costs.

- High-Quality nets for various agricultural needs

- Increased productivity and efficiency

- Economical production solutions

Automatic Shade Net Production Line

The implementation of an automated shade net production line has modernized the manufacturing process. This efficient approach utilizes advanced machinery and technology to manufacture high-quality shade nets with increased speed and accuracy. The line check here automates key tasks, such as cutting the fabric, sealing the net panels, and treating the final product. This results in a more reliable output, reducing labor costs and optimizing overall productivity.

Fabricators of Durable and Reliable Shade Net Fabric

When you need shade net fabric that can withstand the elements and provide reliable protection for years to come, look no further than leading shade net fabricators. These experts understand the importance of using durable materials and employing cutting-edge manufacturing processes to ensure that each shade net is built to last. From residential applications, their shade nets provide effective sun protection while remaining easy to install.

- Choose a fabricator with a proven track record of delivering exceptional shade nets.

- Assess the type of use and choose a shade net designed for your needs.

- Don't compromising on quality – invest in a shade net that will offer reliable performance.

Precision Engineering: Shade Net Making Machines

Shade net production machines are engineered with remarkable precision to generate high-quality shade nets for a variety of applications. These machines utilize advanced technologies, such as automated cutting systems, to provide accurate and consistent fabricsubstrate placement. The result is a durable and long-lasting shade net that provides optimal coverage from the sun's harmful rays.

- Features of precision engineering in shade net making machines include: robust construction, programmed threading systems, and refined cutting mechanisms.

- These machines are suitable for both industrial shade net creation as well as smaller operations.

Amanda Bearse Then & Now!

Amanda Bearse Then & Now! Sydney Simpson Then & Now!

Sydney Simpson Then & Now! Bo Derek Then & Now!

Bo Derek Then & Now! Katey Sagal Then & Now!

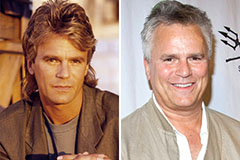

Katey Sagal Then & Now! Richard Dean Anderson Then & Now!

Richard Dean Anderson Then & Now!